Top 10 Performance Metrics for Evaluating Industrial Cooling

Maintenance Requirements

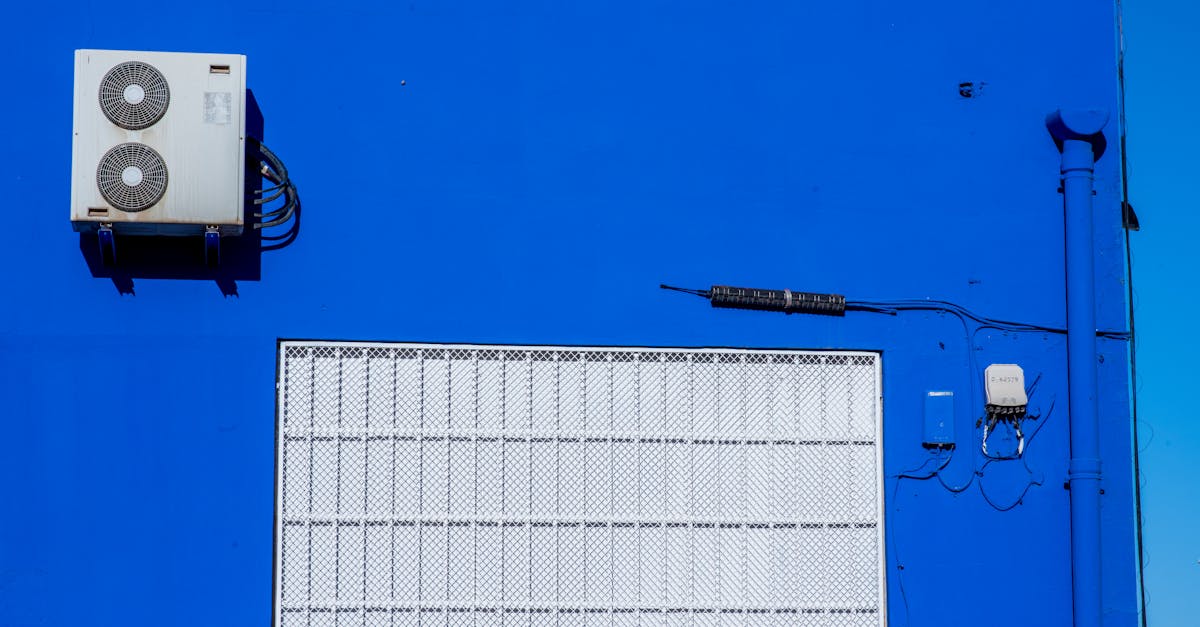

Regular maintenance is essential for ensuring the longevity and effectiveness of industrial cooling systems. These systems often operate under demanding conditions, leading to wear and tear over time. Scheduled inspections allow for the identification of potential issues before they escalate, reducing the likelihood of unexpected breakdowns. A consistent maintenance plan not only prevents disruptions in operations but also optimises energy efficiency, ultimately contributing to cost savings.

Maintenance requirements can vary based on the type of cooling system employed and its specific applications. Factors such as usage frequency, environmental conditions, and manufacturer recommendations play a significant role in determining the necessary upkeep. Understanding these needs can help operators implement tailored strategies, ensuring that components such as filters, fans, and compressors receive the appropriate attention. This proactive approach aids in maintaining optimal performance levels and helps extend the operational life of the entire cooling system.

Evaluating Maintenance Needs for Optimal Performance

Regular maintenance is crucial for ensuring the optimal performance of industrial cooling systems. Scheduled servicing can help identify potential issues before they escalate, reducing the risk of unexpected breakdowns. Maintenance tasks often include inspecting components, cleaning filters, and checking fluid levels. Implementing a systematic approach to maintenance can extend the lifespan of the equipment and enhance overall effectiveness.

It is essential to develop a maintenance plan tailored to the specific requirements of the cooling system in use. Each system has unique operational demands and challenges, making a one-size-fits-all approach less effective. By analysing past performance data and operational records, businesses can determine the appropriate frequency and type of maintenance. This proactive strategy not only contributes to smoother operations but also helps in optimising energy efficiency and reducing operational costs.

Noise Levels

Noise levels in industrial cooling systems are an essential factor to consider when evaluating performance. Excessive noise can not only affect the working environment but may also indicate underlying mechanical issues. Understanding acceptable noise thresholds is crucial for maintaining operational efficiency. Regular monitoring allows for swift identification of any disturbances, which can lead to timely maintenance and adjustments.

When assessing cooling systems, it is important to utilise appropriate measurement methods to quantify noise output. Sound level meters can provide precise readings, enabling comparisons against industry standards. Establishing acceptable limits based on the facility's operational requirements ensures that noise levels remain manageable. By addressing both the sources and types of noise, improvements can be made to enhance overall system performance and workplace comfort.

Measuring Acceptable Noise Levels in Cooling Systems

Industrial cooling systems are often essential to maintain operational efficiency, but they can also generate considerable noise. Evaluating the acceptable noise levels is crucial for ensuring comfort and compliance with regulations. Many industries have established guidelines regarding permissible sound levels, which are measured in decibels (dB). These standards often vary based on the application and environment, taking into account factors such as proximity to workspaces or residential areas.

To measure noise levels effectively, it is essential to use appropriate sound-level meters that can capture both continuous and fluctuating sounds. Regular assessments should be conducted during operational hours to provide accurate readings. Understanding the baseline noise levels in a facility allows for identifying any significant deviations that may indicate operational issues or equipment fatigue. By quantifying noise production, companies can address potential disturbances proactively, ensuring a quieter and more productive work environment.

Return on Investment (ROI)

Assessing the return on investment for industrial cooling system upgrades is crucial for stakeholders. This metric typically looks at the cost savings generated by enhanced efficiency, reduced energy consumption, and lower maintenance costs. A systematic approach involves calculating the initial expenses associated with purchasing and installing the new system, while also considering the potential reduction in operational costs over its lifespan.

In addition to direct financial benefits, potential gains in productivity and reliability should also be factored into the ROI analysis. Improved cooling systems often lead to increased equipment lifespan, reduced downtime, and enhanced working conditions for employees. By evaluating these aspects, businesses can gain a comprehensive understanding of how upgrades contribute to overall financial health and operational performance.

Calculating ROI for Cooling System Upgrades

For businesses investing in cooling system upgrades, determining the return on investment is crucial. This process typically begins with assessing the overall costs associated with the upgrade, including installation, equipment purchase, and maintenance. Simultaneously, companies should consider potential savings in energy consumption and operational efficiency. Evaluating these factors enables organisations to estimate how long it will take for the upgrades to pay for themselves through reduced energy bills and enhanced productivity.

Once the initial costs and potential savings are calculated, companies can use these figures to analyse the ROI over a defined period, often expressed as a percentage. This metric aids decision-makers in understanding the long-term financial benefits of the upgrade. Additionally, considering intangible benefits, such as improved employee comfort or environmental compliance, can further inform the evaluation process. This comprehensive analysis ultimately aids organisations in making informed choices regarding their cooling systems.

FAQS

What are the key performance metrics for evaluating industrial cooling systems?

The key performance metrics for evaluating industrial cooling systems include maintenance requirements, noise levels, return on investment (ROI), energy efficiency, cooling capacity, reliability, operational costs, environmental impact, system responsiveness, and life cycle costs.

How can I determine the maintenance requirements for my cooling system?

To determine the maintenance requirements, it is important to assess the manufacturer's guidelines, monitor the system's performance regularly, and evaluate the specific conditions of your operational environment. Regular inspections and preventive maintenance schedules are also crucial for optimal performance.

Why are noise levels an important metric in industrial cooling?

Noise levels are important because excessive noise can lead to workplace discomfort, affect employee productivity, and may violate occupational health standards. Measuring and managing acceptable noise levels ensures a better working environment while maintaining system efficiency.

How do I calculate the return on investment (ROI) for cooling system upgrades?

To calculate ROI for cooling system upgrades, you can compare the cost of the upgrades to the savings generated from improved energy efficiency, reduced maintenance costs, and extended equipment lifespan, typically expressed as a percentage or a ratio over a specific period.

What factors influence the energy efficiency of a cooling system?

Factors influencing energy efficiency include the system's design and technology, the quality of insulation and sealing, the type of refrigerant used, operational practices, and regular maintenance. Improving any of these can significantly enhance overall energy efficiency.

Related Links

Roundup of Innovative Approaches to Cooling Efficiency MeasurementReview of Best Practices for Cooling Efficiency Assessment

Historical Advances in Cooling Efficiency Metrics

Why Data Monitoring Enhances Cooling Efficiency

Why Efficiency Metrics are Crucial for Industrial Cooling

What are the Key Performance Indicators for Cooling Systems

What to Look for in Cooling Efficiency Benchmarking

How to Improve the Performance Metrics of Your Cooling Solutions